Product Details

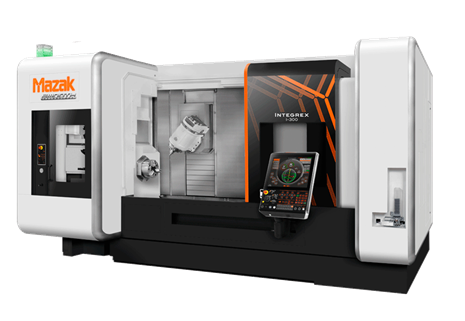

INTEGREX i-200

INTEGREX i-300

INTEGREX i-400

Product Details

The INTEGREX is the most widely used multi-tasking machine tool in the world. A wide range of specifications is available to meet a variety of process integration requirements. INTEGREX i-series, the fifth generation Mazak multi-tasking machine, features a large machining area and high accuracy performance plus unsurpassed ease of operation thanks to the ergonomic machine design. Combination of several cutting processes, including turning, milling, drilling, tapping and deep - hole boring from raw material input to final machining, entire process in a single setup can be DONE IN ONE® operation.

Product Specification

| Item | Unit | INTEGREX i-200 | INTEGREX i-300 | INTEGREX i-400 | |

|---|---|---|---|---|---|

| Capacity | Maximum Swing | mm | Ø658 | ||

| Max Machining Diameter | mm | Ø658 | |||

| Max Machining Capacity | mm | Ø65 | Ø80 | Ø102 | |

| Max Machining Length | mm | 1011 | |||

| Main Spindle | Chuck Size | inch | 8 | 10 | 12 |

| Maximum Speed | min-1 | 5,000 | 4,000 | 3,300 | |

| Motor Output (30min rating) | kW | 22 | 30 | ||

| Milling Spindle | B-Axis Travel | degree | 240° | ||

| Magazine Capacity | - | 36 | |||

| Maximum Speed | min-1 | 12,000 | |||

| Motor Output (40 ED rating) | kW | 22 | |||

| Feed Axes | Travel (X Axis) | mm | 615 | ||

| Travel (Y Axis) | mm | 260 | |||

| Travel (Z Axis) | mm | 1,077 | |||